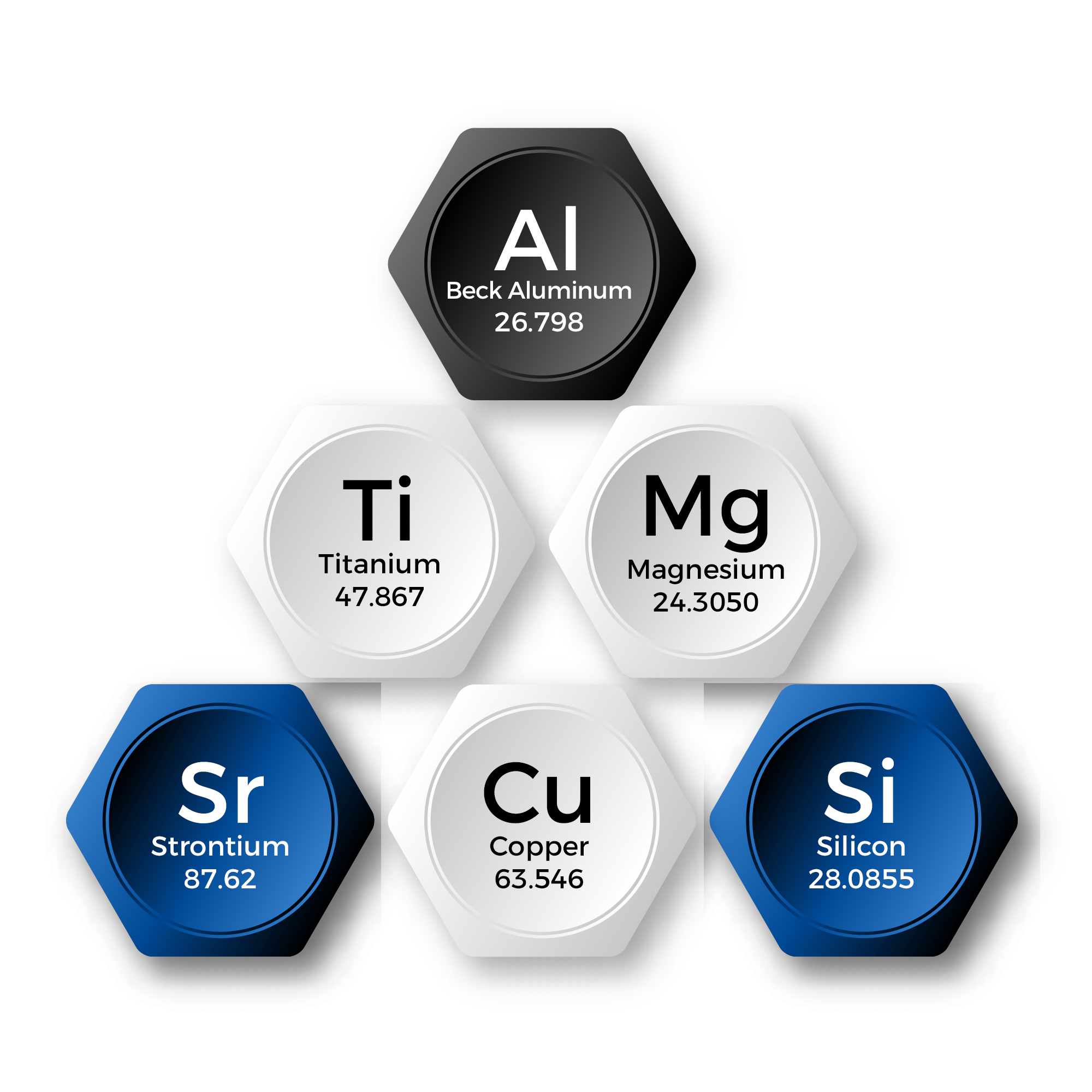

Master Alloys

Aluminum master alloys are also commonly referred to as grain refiners, modifiers or hardeners, depending on their application. Master alloys are specific elements added to aluminum alloys to produce a particular alloy, modify a melt or to produce castings with desired mechanical properties, such as greater mechanical strength, ductility, castability or surface appearance. Applications like this are why master alloys can be a smart business solution to adjust the properties of certain aluminum products, whether for technical or economical reasons – or both.

Beck Aluminum markets and distributes the Master Alloy products of Aleastur Group. Aleastur Group produces a comprehensive range of master alloys for the aluminum casting industry at its production facilities in Spain and Bahrain. Master alloys are available in various forms and chemical compositions. Contact your Beck Aluminum representative for selection and use.

Product Forms

Coil

Contibar

Cut Rod

Waffle Plate

Master Alloys

Used to enhance physical and mechanical properties of aluminum alloys.

- Aluminum – Boron

- Aluminum – Chrome

- Aluminum – Copper

- Aluminum – Iron

- Aluminum – Magnesium

- Aluminum – Manganese

- Aluminum – Nickel

- Aluminum – Silicon

- Aluminum – Strontium

- Aluminum – Vanadium

- Aluminum – Zinc

- Aluminum – Zirconium

Grain Refiners

Used for controlling the dispersion of individual crystals in metals to produce a finer and more uniform grain structure.

- Aluminum – Titanium

- Aluminum – Titanium – Boron

- Aluminum – Titanium – Carbon